當前位置:首頁 > 產品中心

當前位置:首頁 > 產品中心

Application:

The G150 is designed for multi colors decoration of all shapes of glass bottles, cups, mugs at high production speeds. It can print any shape of containers all around in 1 print. It is suitable for glass containers printing with UV ink or thermoplastic ink. All servo driven and fast speed make the G150 ideal for off-line or in-line 24/7 production.

General Description:

1.Automatic loading system with multi axis servo robot.

2.Servo driven transfer system.

3.Automatic printing system with all servo driven: printing head, mesh frame, rotation, container up/down all driven by servo motors.

4.Automatic UV curing with high efficiency electrode UV system from Europe.

5.Super quick and easy change over from one product to another. All parameters automatic setting simply in touch screen. Product change is 15 minutes only per color.

6.All Ethercat servo motors with industrial PLC control & touch screen operation system, internet cable connection available, easy for future maintenance and upgrading.

7.Automatic unloading with servo robot.

8.Safety operation with CE .

9.Repeat print to be multi colors.

Options:

1.Flame Plasma pre-treatment system for best adhesion on glass

2.Additional module up to 10 units, to be multi colors production line

3.New shape program upgrading through internet

Additional models and remarks:

G150C: machine equipped with camera vision system, for cylindrical products without registration point. Repeat print to be multi colors.

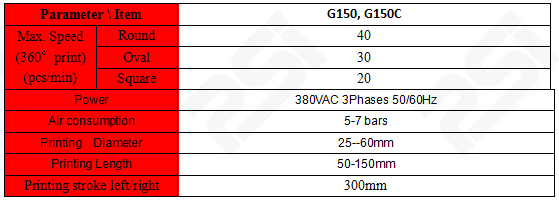

Tech-data :

Samples: